memsstar Offers New Vacuum Vapour-Phase Metal-Assisted Chemical Etching Technology

Co-Developed with PSI and Fraunhofer ENAS, MacEtch Technology Enables Scalable Plasma-Free Silicon Etching

LIVINGSTON, Scotland, Nov. 19, 2025 (GLOBE NEWSWIRE) -- memsstar Ltd., a leading provider of etch and deposition equipment to researchers and manufacturers of semiconductors and micro-electrical mechanical systems (MEMS), today announced it is now offering a breakthrough vacuum vapour-phase metal-assisted chemical etching (MacEtch) technology. Developed in collaboration with the Paul Scherrer Institute (PSI) and Fraunhofer ENAS, the new approach represents a significant advance in highly controlled, anisotropic silicon etching for next-generation micro- and nanoscale architectures.

Metal-assisted chemical etching is an electrochemical, plasma-free silicon etch process that leverages patterned metal catalysts—typically platinum—to drive highly directional etching. While liquid-phase MacEtch is widely studied, memsstar and its research partners have demonstrated a vapour-phase MacEtch method that delivers substantially reduced porosity, improved uniformity, and exceptional suitability for extremely high aspect ratio nanostructures. Early results confirm that vapour-phase MacEtch offers a more controllable, reproducible etch mechanism with sharply defined silicon profiles, enabled by precise gas-phase control and in-process endpoint detection to monitor silicon tetrafluoride (SiF₄) formation.

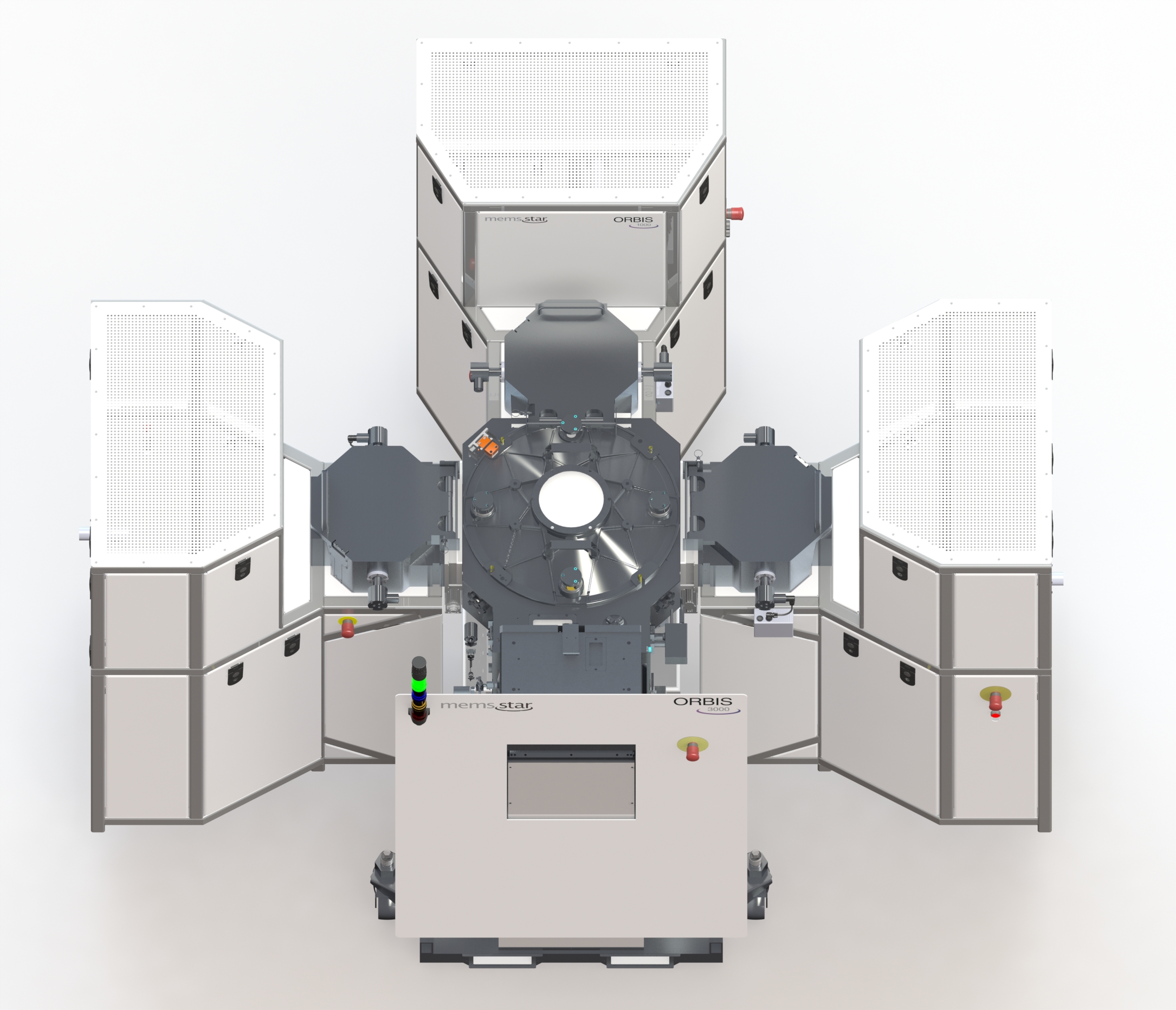

The new technology is implemented on memsstar’s ORBIS platform, enabling finely tuned, programmable gas flows that decouple key MacEtch parameters, including oxidant composition, carrier gases, temperature, and partial pressures. The system supports up to 8-inch wafers and includes in-situ plasma cleaning to ensure consistent catalyst behaviour across large substrates. Demonstrations have shown uniform etch profiles across full 4-inch wafers, as well as nanowire structures with diameters as small as 100 nm and aspect ratios exceeding 430:1.

Beyond enabling MacEtch, the vapour-phase module can be clustered with additional memsstar process technologies to create a versatile, integrated platform tailored to customers’ manufacturing needs. Available clustered capabilities include:

- A thermal pre-treatment station to optimise metal catalyst morphology

- A remote plasma source for in-situ pre- and post-plasma surface treatments

- A self-assembled monolayer (SAM) coating module for surface functionalisation and anti-stiction protection without exposure to ambient atmosphere

The joint programme will now focus on exploring fundamental MacEtch parameters to advance scalability, reproducibility, and compatibility across a wide range of device geometries and applications. Target markets include MEMS, microfluidics, metamaterials, photovoltaics, X-ray and photonic devices, sensors, and advanced semiconductor packaging.

“This collaboration showcases how vapour-phase MacEtch can unlock entirely new design possibilities for advanced silicon micro- and nanostructures,” said memsstar CEO Tony McKie. “By engineering tight process control in vacuum, we are providing customers with new levels of anisotropy, uniformity and integration flexibility.”

To learn more about the MacEtch technology and memsstar’s product portfolio, visit memsstar in the TechWorks booth B1121 during this week’s SEMICON Europa at Messe München in Munich, Germany.

About memsstar Limited

memsstar Limited is a leading provider of deposition and etch equipment – including its ORBIS platform portfolio and proprietary process modules – as well as technology products and services to manufacturers of semiconductors and micro-electrical mechanical systems (MEMS). The company’s remanufactured etch and deposition equipment and its proprietary technology solutions support the European semiconductor market and the global MEMS market. memsstar delivers proprietary process technology and equipment to help the MEMS industry meet the challenges of developing and manufacturing increasingly complex and integrated MEMS devices. For more information, visit https://memsstar.com

| For more information, contact: | |

| Tony McKie | Lisa Gillette-Martin |

| memsstar | Kiterocket |

| tel: +44 (0) 1506 243188 | tel: +1 408.205.4732 |

| email: tony_mckie@memsstar.com | email: lgmartin@kiterocket.com |

ORBIS is a trademark of memsstar Ltd.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/deea2c17-e35e-4eb8-9074-4d362520207a

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.